The world population is increasing and the demand for plastic is growing at unprecedented rates and while this continues we are standing on the front row of the greatest, most unprecedented, plastic waste tide ever faced. For more than 50 years, global production and consumption of plastics have continued to rise. An estimated 299 million tons of plastics were produced in 2013, representing a 4 percent increase over 2012. Plastic is a key material in the world economy, found in cars, mobile phones, toys, clothes, packaging, medical devices, and much more.

Plastic is versatile, lightweight, flexible, moisture resistant, strong, and relatively inexpensive. These are the attractive qualities that lead us, around the world, to such a voracious appetite and over-consumption of plastic goods. However, durable and very slow to degrade, plastic materials that are used in the production of so many products all, ultimately, become waste.

Our tremendous attraction to plastic, coupled with an undeniable behavioural propensity of increasingly over-consuming, discarding, littering and thus polluting, has become a combination of lethal nature. Marine life is facing “irreparable damage” from the millions of tonnes of plastic waste which ends up in the oceans each year. Up to 13 million tons of plastic waste end up in the ocean each year; by 2050, there could be more plastic in there than fish.

Plastic, whatever its nature is Globally the no 1 waste issue.

Environmental responsibility has gained significant momentum in light of dwindling natural resources, unmanageable waste deposits and consumer consciousness to select products which are sustainable and recyclable. Every cartridge saved from landfills can make a difference. The highly durable plastic and metal materials used in the production of printing components make the re-manufacture of cartridges an economically viable and earth-friendly solution. When choosing EcoTeq as your supplier for re-manufactured toner cartridges, you partner with a company that pursues environmental sustainability seriously. Additionally, the re-manufacture of cartridges has the benefit of ensuring a steep decline in waste deposits and a significant reduction in volatile contaminants being absorbed by ground, air and water.

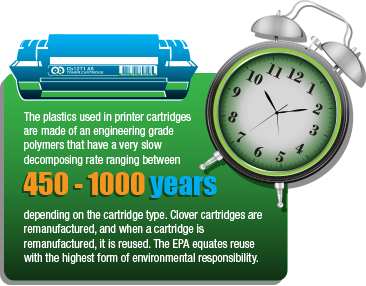

Each year more than 60 million kilos of cartridges are discarded in landfills, while the average toner cartridge can actually be remanufactured more than once. For a toner cartridge to fully decompose in a landfill site, it takes between 450 and 1000 years, which gives you an extent of how damaging these cartridges can be to the environment. The conservation of oil should also be considered – for every printer cartridge which is recycled, roughly 3.8 litres of crude oil is used.

Remanufacturing a toner cartridge means that it is reused and recycled. Recycling conserves energy and natural resources now and for future generations.

Our range of remanufactured toner cartridges are a truly an eco-friendly alternative. Start contributing to the protection of our valuable planet today and purchase our high quality remanufactured products. If the products purchased reach their end of life, simply return them to us and we add them to the recycling loop.

Think green, act green!

According to data provided by the IDC in 2012, approximately 1.3 billion inkjet cartridges were used, with less than 30% recycled. In one year, if the world’s discarded cartridges were stacked end to end, they would circle the earth twice.

Despite the environmental and bottom-line benefits of recycling print cartridges, every year over 350 million cartridges with a combined weight of 150 million pounds are buried in our nation’s landfills; that is equivalent to the weight of 20,000 African elephants.

This equates to an average of 11 cartridges being thrown away every second, 660 cartridges per minute, 39 600 cartridges an hour, 950 400 cartridges a day and astounding 6 652 800 cartridges in one week.

- It takes 3.8Kg of oil to produce every new toner/laser cartridge.

- For inkjet cartridges, you require 85 grams of oil.

- One single toner cartridge emits around 4.8kg CO2 Greenhouse Gases per cartridge, this figure does not consider the toner inside

- Generally, a cartridge that yields five thousand pages contains 200 grams of toner, which means that the CO2 emission per cartridge is 3.2 kg.

- People can reduce landfilling when they recycle toner cartridges. Every remanufactured laser cartridge saves nearly 0,9 kg of metal & plastic waste from being deposited in landfills. Toner cartridge remanufacturing saves over 38,000 tons of plastic and metal from landfills.

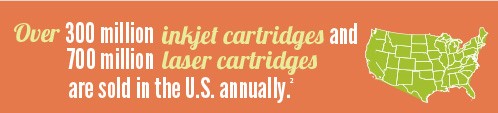

In the USA over 300 million Inkjet cartridges and 700 million laser cartridges are sold annually. Unfortunately, over 300 million of these cartridges end up in landfills and have a combined weight of over 68 000 000 million Kilograms.With 8 ink cartridges thrown away every second. It takes up to 450 years for one of these laser cartridges to decompose.

South Africa sells an estimate of 11 million cartridges every year and only about 30% of these are recycled. This means an alarming 70% end up in landfills. It takes anywhere from 450 to 1000 years for ink and toner cartridges to fully decompose. This is dependent on the plastic used. Some toners are made from industrial grade plastic thus increasing the time it takes to decompose.

Toner and ink cartridges that land up in landfills cause severe environmental damage as they leak toxic chemicals and hazardous waste materials into the soil, causing alarming damage to our ecosystem. Each ink cartridge produced carries a carbon footprint of 4.5kg of Carbon Dioxide (CO2).

Furthermore, the plastic they are made of is manufactured using an estimated two litres of crude oil per cartridge, which is a dangerous waste considering crude oil is a non-renewable resource. Making recycling even more important as this can save up to 40 million litres of oil every year.

A laser printer alone is responsible for around 45 kilograms of waste every year so if one-person reuses or recycles their used cartridges it saves an estimated 45 Kilograms of hazardous waste per year.

By choosing to sell remanufactured cartridges from EcoTeq, you can make a 44% smaller environmental footprint over purchasing an OEM cartridge. Every saving achieved benefits the cause of being more environmentally conscious, thereby conserving our valuable planet.